General Knowledge About S330 Steel Shot

General Knowledge About S330 Steel Shot

S330 steel shot is made from high-quality stainless steel and is available in 55-pound bags. Its diameter is 1.0 mm, and it achieves good coverage quickly. S330 Steel Shot is very useful in sandblasting and descaling processes. Its uniform hardness, good cleaning effect, and durable wear make it suitable for castings. Its cleaning and processing effect is visible, and its consistent hardness and uniform wear properties make it ideal for all kinds of applications.

The main uses of s330 steel shot are blasting and shot peening operations.

They are also widely used in the container, ship, auto, and locomotive industries. They are used for blasting and peening applications. These high-carbon shots are produced through a centrifugal process that replaces high water jet streams. It is high in resistance to impact fatigue and has a fast cleaning rate. The high carbon content of the shot also results in high hardness and good surface pressure resistance.

S330 steel shot is an excellent choice for blasting applications.

It is a versatile material used in many industries, from steel construction to the container, ship, and automobile industries. The high hardness and microstructure make it an excellent choice for various projects. Its durability makes it ideal for all kinds of blasting applications. This is because it can withstand extreme temperatures and high pressure.

It is widely used in blasting and shot peening. It is also used in the container, ship, and automobile industries. The microstructure of steel shot makes it easy to handle and improves the strength of parts. It is one of the leading manufacturers in China and is backed by a reputable company. The advantages of using this material are numerous. Its durability and microstructure allow it to be used in various industries.

Steel shot is an essential abrasive material in many applications.

Its microstructure makes it ideal for the shot peening and is used in casting and mechanical industries. Its spherical shape makes it suitable for blast room and blast machine applications. In addition, it is widely used for various other applications, including machining and welding. Its high hardness makes it ideal for steel rust removal and surface strengthening applications.

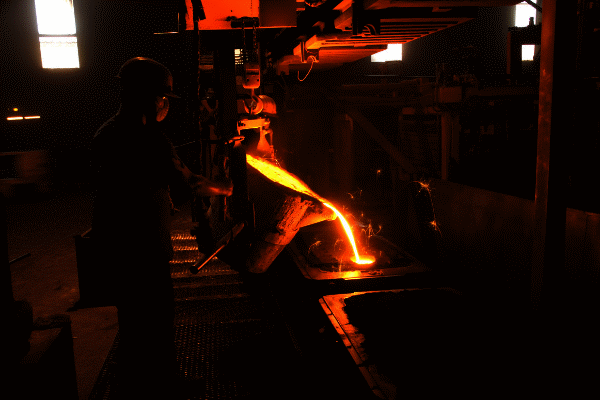

High carbon steel shot is manufactured by atomization of molten steel.

The steel shot produced through this process is characterized by its high resistance to impact fatigue and quick cleaning rate. The spherical shape of the s330 steel shot helps it be a valuable tool in various applications. It is commonly used in machining, blast cleaning, and shot peening. It is a versatile material and is available in many sizes.

Steel shot is used in a variety of applications.

Its compacting action provides compressive strength to metal parts. It can be found in different hardness levels, ranging from 41 to 51 HRC. Besides, it is resistant to impact fatigue and has a fast cleaning rate. The high carbon steel shot is the perfect material for blast cleaning and forging. This material is also used in foundries. In general, it is the most cost-effective abrasive material in industrial processes.

Steel shot is an alloy of iron and carbon.

It is a lightweight and durable material used in blast cleaning, shot peening, and surface polishing. Among the many applications of steel shot, it is the most widely used in airless wheel blast machines. Unlike other materials, it is easy to work with and spherical. Its sharp edges and rounded edges make it the perfect material for various applications.

S330 steel shot is made from molten steel used in blast cleaning and shot peening. S330 steel shot has a hardness range of 41-51 HRC and is a high-quality product that is extremely useful in industrial settings. It is also common in industrial settings, such as forge shops. You can choose the type of shot that works best for your specific needs. It is not only affordable, but it is highly durable.

Telephone :+86 157 6285 8378

Telephone :+86 157 6285 8378 WhatsApp :+86 157 6285 8378

WhatsApp :+86 157 6285 8378 Email :info@ziboyalong.com

Email :info@ziboyalong.com