What is steel shot used for?

1. Steel shot is widely used to remove oxidation and rust from steel workpieces before painting, in which centrifugal photo blasting equipment is often used. The round ball shape and small hardness of the steel shot do not cause much wear to the equipment.

2. Steel shot is also widely used for sand cleaning of castings. When used with the proper equipment, a steel shot is the best abrasive for your surface cleaning because of its durability.

3. Applicable industrial range of steel shot

Aerospace industry; automotive industry; sandblasters/painters; consumer goods manufacturing; container manufacturing/repair; foundry.

Granite/stone cutting; shipbuilding and repair; oil and gas pipelines; plant maintenance and metalworking.

Applicable process areas

Surface pre-treatment before painting, sand cleaning, pipe descaling, strengthening

Steel Shot Recommend Products

Steel Shot Detail Introduction

What is the definition of steel shot?

Steel Shot is a spherical particle made of unique materials by special heat treatment.

Steel shot as a standard metal workpiece treatment material. Steel shot has a tight organization uniform particle size. The surface of the metal workpiece treated with steel shot can increase the surface pressure of the metal workpiece and can be very good for improving the fatigue resistance of the workpiece.

What are the characteristics of using steel shot to treat the surface of metal workpieces?

It has the characteristics of fast cleaning speed.

Specific details: steel shot and steel sand have the appropriate hardness, have a good rebound, internal corner, and complex shape of the workpiece can be cleaned evenly and quickly, shorten the surface treatment time, improve efficiency, is a suitable surface treatment materials.

What is the process of making steel shots?

Firstly, melt high-quality steel blocks, wool, steel scraps, and then use the centrifugal discs to shape the molten steel into the water at high speed. The surface temperature of the steel shot drops sharply to form the shot body quenched once. After the direct quenching, the image is dried, reheated, and tempered in a furnace to achieve suitable hardness. The tempered steel shot is sorted through a mechanical screen into SAE compliant grades for use in blasting equipment.

The excellent heat treatment control process gives the shot the best elasticity and fatigue resistance. The different grit sizes and hardnesses are suitable for other methods, such as shot peening of high volume and heavy parts or materials.

What are the types of steel shots?

(1) Steel shot

The hardness of steel shot is generally HRC40~50; processing hard metal, the hardness can be increased to HRC57~62. Their toughness is better, the service life is several times of cast iron shot, widely used.

(2) Cast iron shot

The cast-iron shot hardness of HRC58 ~ 65 is very brittle, easy to break, short life, not widely used. It is mainly used in places where high shot strength is required.

(3) Glass shot

Glass shot has a lower hardness than the first two kinds of ammunition, mainly used for stainless steel, titanium, aluminum, magnesium, and other cases where iron contamination is not allowed. It can also be used in steel after blasting for a second treatment to remove iron contamination and reduce the roughness of the surface of the parts.

What are the technical standards for steel shot?

Main technical requirements of high carbon steel shot

Specification grade: S400 to S030.

Microhardness: 390HV-530HV.

Chemical composition: carbon: 0.8%-1.2%, manganese: 0.6%-1.2%, silicon: 0.4%-1.2%, sulfur, phosphorus: ≤0.05%.

Metallographic organization: tempered martensite or tempered quartzite.

Density ≥ 7.0 g/cm3.

Total defects ≤ 10%.

Foreign impurities ≤ 1%.

Water content ≤ 0.2%.

The original standard GB6484-86 cast steel shot was abolished in 1993.

Because of the annealed iron shot, the surface color shows uniform blue, often using tempered iron shot pretending to be cast steel shot, iron shot service life of only 50-400 times, iron shot rust removal effect is seriously reduced, seriously damage the interests of users.

Other

The market chromium-molybdenum steel shot manganese steel shot are manufacturers of the concept of propaganda words. Suppose you add 1% of metal molybdenum In that case, it is necessary to increase 10kg of metal molybdenum per ton of steel shot, requiring 4,000 yuan. The domestic iron shot is only sold for bout 3,000 yuan/ton. Metallographic organization: tempered martensite tempered quartzite reticulated carbide greater than grade 3.

Hardness: 45---65HRC Density: 7.58g/cm3

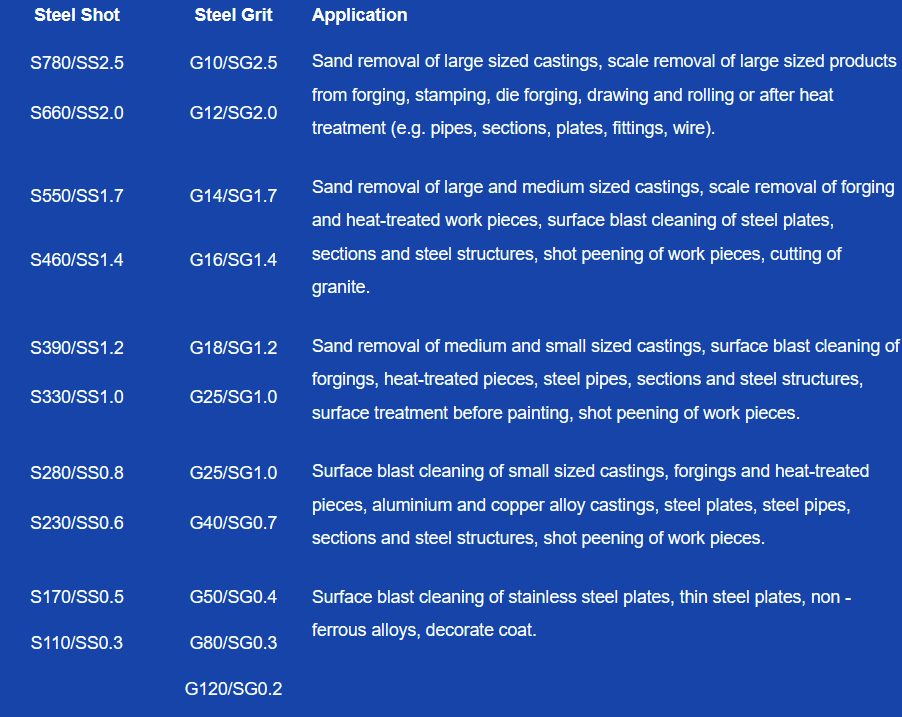

Technical parameters table of steel shot & steel grit

What Are the Raw Materials For Producing Steel Shot?

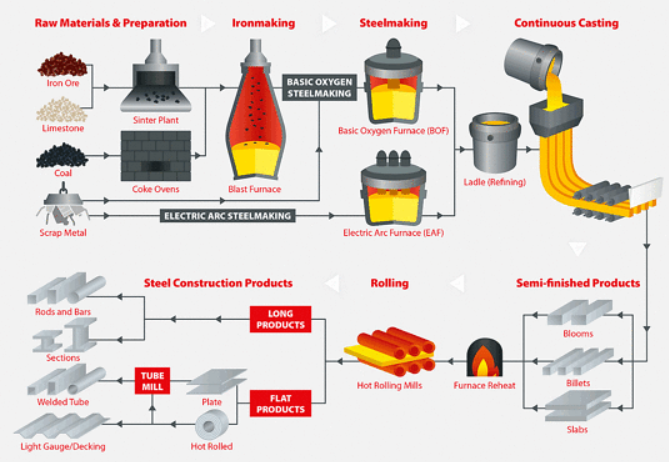

Steel shot is a kind of round ball molding by steel material, which is the main material of blast cleaning. Steel shot can be used in the shipbuilding industry, railway, bridge, and other construction engineering or metal processing industry, etc. Raw materials for producing steel shot can be divided into three types: common carbon steel, medium carbon steel, and high carbon steel.

Common Carbon Steel: This material has low cost and good toughness. It can be divided into low-carbon steel and medium-carbon steel. It is mostly used to produce big-size steel grits (G14-G120), steel shots (S930-S780), and cut wire shots (0.6mm).

Medium Carbon Steel: This material has high hardness and good toughness. It can be divided into medium-carbon steel and high-carbon steel. It is mostly used to produce middle-size steel grits (G14-G120), steel shots (S930-S780), and cut wire shots (0.6mm).

High Carbon Steel: This material has high hardness and poor toughness. It is mostly used to produce small size steel grits (G14-G120), steel shots (S930-S780)

How Do You Produce Steel Shot?

One of the questions that many people have is, "How do you produce steel sho ?" The answer depends on the material used. There are two primary methods: the mold and the cut wire methods. The molding method involves pouring molten steel into a mold then removed during the disintegration process. The extruded metal remains on the steel shot, and I then removed it during the finishing process. The cut wire method is the latest in manufacturing methods. Still, it involves cutting a wire and then squeezing it between two pieces of plastic.

Then, the steel shot is fed into a machine that cr shes and cuts the metal into a round shape. During the cold heading process, excess metal r mains on the shot and it has a longer life. After the steel shot has been shaped, it goes ththegh a second process called rough grinding. This step uses abrasive compounds to remove the last layer of steel. Once the shot is finished, it passes through a grinding machine to reduce it to a very small size.

Once the shot is in the right size, it t tenses through a rough grinding machine. After this, it then goes through a lapping machine that uses abrasive compounds to remove the final layer. This step gives the steel shot a smooth finish. The lapping machine can finish a batch in a single day or as long as 10 hours. The time required will depend on the desired precision of the shot.

Once the steel shot has gone through the lapping machine, it must undergo a series of rou h grinding processes. The first step is to re oversell the flashing. The next step is to pass it through an h at the treatment machine. The heat treatment increases the strength of the metal. The final step is grinding, which will remove any remaining metal, leaving a smooth surface. The last step is sanding.

The production process of steel shot is an important operation in the primary met l production process. The different steel shot sizes produce the same quality and results, resulting in superior cleans or the metal surface. The larger steel shot blasting process is more effective for rougher surfaces. The air pneumatic system accelerated the scattershot on the surface. This method will increase th cleaning efficiency. The sandblasting machine will be more efficient if the shots are smaller than the other sizes.

While making steel shots differs from one mill to another, the process also involves the ma uffacturef of the shot. It is essential to ensure that the quality of the steel is consistent and that it meets the requirements of the industry. If you want to produce a high-quality shot, you should ensure that the material is of good quality. If it is not, you should not make any changes in the production procedure. It is not a good idea to try different grades of shot.

What Can You Make With Steel Shot?

Steel shot is a rounded media produced using a variety of processes. It is commonly used for peening and deburring metal, as well as for texturing concrete. However, it can also be made from recycled steel. Here's how to make steel shots yourself! Read on to learn more! Let's get started! What Can You Make With It? - The Most Common Types

Steel shot is a bluish-gray alloy of iron and carbon. It can be plated with zinc to prevent rust, depending on its application. It can withstand a variety of load forces. It is classified according to different ballistic industry standards based on its softness, shape consistency, and overall quality. It is used in many industries and is the best choice for many applications.

Another important application of steel shot is in shot peening. This technique involves repeatedly striking a workpiece's surface with a steel shot. The impact causes the workpiece's surface to deform, making it more durable. These products are used in many different manufacturing processes and can be found in various industries.

One of the main benefits of casting your steel shot is that it is more uniform. Despite this, it is still necessary to temper your guns to get a better result. Unlike steel pellets, cast steel shot is very difficult to break, so it is important to use a gun that has an accurate abrasive power rating. Once your rifle is ready, steel shot is the next best thing.

While steel shot is much harder to recycle than lead, it is still far more cost-effective and durable. It's widely used in primary metal production. Smaller steel shot blasting is used for rougher surfaces, while larger ones are used for smoother surfaces. In addition, a wheel blast system can accelerate the steel shot on the surface and produce a superb result. A pneumatic or wheel blast system will accelerate the steel shot and produce a smooth finish on the metal.

Aside from making steel shots, you can also use it in your gun. Unlike lead, steel shot has less energy. But unlike lead, it does not have as much energy as a lead shot. It is also a better choice than lead. Its low price makes it a popular choice for surface preparation. There are many advantages of making it. It is a cheap and effective way to produce the texture you want in your workpieces.

Stainless steel shot is also available. Its consistency makes it perfect for deburring stampings and other fabrications. It can even be used in ball bearings. A typical shot is a ball with one steel ball in its middle. It can be used in some different ways. It is a great choice whether it's for a bicycle tire, a helicopter's rotor, or a computer mouse.

Types of Metalworking Shots

A variety of different shots are available from manufacturers who are specialized in this type of metalworking. The most common type is steel shot, but other types can include aluminum, brass, copper, and zinc. The use of shot allows you to refine your material without causing further damage. For example, you can use aluminum shot to smooth out a rough surface. Another type of metal working mater is steel shot, which is also known as microspheres.

Shot blasting is best suited to larger projects. The abrasive process allows you to prepare even the toughest surfaces with high-quality results. It is ideal for large-scale continuous and batch processes. The process is highly versatile and is used in various industries, including the oil and gas industry, automotive industry, and more. It can remove rust, oxidation, and rust from welding jobs and can even be used to clean tank hulls. It is essential for repairing engines, which require intensive abrasive treatment.

Shot is a great choice for many types of metalworking. Its characteristics make it an excellent choice for deburring, peening, and surface preparation. Cast steel shot is often used in die castings and is ideal for removing release agents and cleaning molds. It is available in custom-blended Work Mixes, which can be used in centrifugal wheel machines.

Steel shot also known as microspheres a popular metalworking material. It is a lightweight, efficient, and safe material. The shot is made of abrasive steel that is composed of iron and manganese. Its chemical composition makes it an effective metalworking mater. Despite the high cost, steel shot can be easily transported to the Jobsite or rented on an ad hoc basis.

Unlike other abrasives, steel shot is an effective metalworking material. Its uniform size and hardness make it an excellent abrasive. In contrast, sand cannot withstand many impacts, while steel shot is capable of enduring hundreds. Its advantages over other abrasives are outlined below: If you need a durable and flexible material, choose abrasive.

Despite its small size, steel shot still aids in cleaning. It is a durable material, capable of absorbing hundreds of impacts. When properly used, steel shot is an effective and cost-efficient metalworking mater. The material is a versatile tool, but you should always consider the safety of the materials you're using. It can cause silicosis if it is not handled properly.

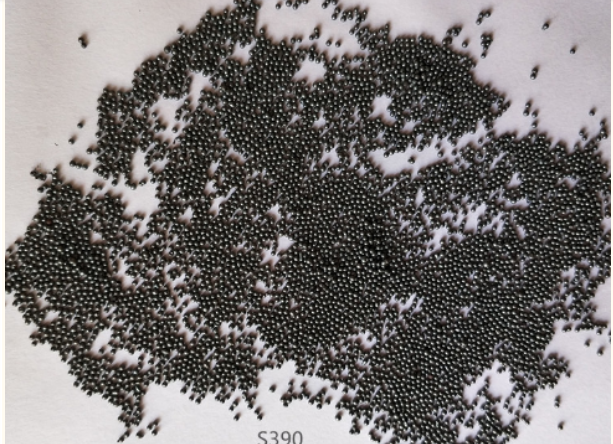

Product Features of S390 Steel Shot From China

S390 steel shot is used widely in blasting and shot peening. It is used in casting, mechanical, container, shipbuilding, and steel industries. It is available in various sizes and packings. Its chemical composition is : 58-92%, microhardness 110-300HV, and high strength. It has a long service life. There are several advantages of using this type of shot, including its low cost and high quality.

Generally, it is made of low carbon steel. Its low hardness is one of its main defects. But the grit is not brittle and pliable, it is easily shaped. Moreover, it releases energy well. Hence, s390 steel shot from China is an excellent choice for blasting applications. Its low cost and high quality make it an excellent choice for industrial applications.

S390 steel shot from China is made of scrap steel and a variety of rare metals and alloys. It is sprayed using a high-pressure water spray gun and formed into a pellet. Once it is made, the formed pellets are reheated and tempered. After quenching, they are dried and sieved through a mechanical screen. Its quality management and chemical composition are strict. Its fine and consistent particles are used for different processes. It has high hardness and high impact resistance, and it is widely used in the automotive industry and construction industry.

Product Features of S170 Steel Shot From China

s170 steel shot is a kind of artificial metal abrasive used widely in industrial applications. The diameter of this abrasive is 0.5mm, which makes it easy to achieve a high coverage rate in a short time. It is also very durable and wear-resistant. Other features of the S170 steel shot are high work efficiency and tight organization. It has moderate hardness and high impact resistance.

S170 steel shot is made of tempered steel. It has a nice microstructure and homogenous hardness. Its abrasive properties include less consumption, well resistance, and cr included. It is available in different sizes, which allow for different requirements. It can be packaged as 25kg per bag and 40 bags on a ton-size wooden pallet. Its abrasive properties make it suitable for blasting and cleaning applications.

It is a good choice for surface cleaning and the removal of corrosion. Its homogeneous hardness and good microstructure make it the best choice for a wide range of applications. It can be produced in a variety of sizes and is suitable for abrasive blasting. It is packaged in 25kg bags on a 1-ton wooden pallet. The price of the S170 steel shot from China depends on the specifications and the quantity of your order.

S170 steel shot is the most popular material for shot blasting. The size of the steel shots and the grade determines the overall finish of the metal. The round ball shape of the steel shot gives the finished product a smooth, polished, and clean surface. Additionally, it imparts compressive strength to metal parts. This material is ideal for a variety of uses. It is used in shipbuilding, middlemen, and other industries.

Product Features of S230 Steel Shot From China

Cast steel shot is a common type of blast media used in the construction industry. It is typically manufactured using premium-grade scrap steel that contains the right proportion of alloys and rare metals. It is manufactured by atomizing the molten metal before pouring it into a water tank, where it is screened for size. It is then quenched and tempered in a special heat-treating process. Then, it is packaged in different types of packages to meet the needs of various users.

S230 steel shot is packaged in paper bags, 25kg per bag, or forty bags per plywood pallet. It can be delivered in custom-sized bags to meet the requirements of various customers. The shipment can be done within ten days after order confirmation. The manufacturer of this grit will offer customized packaging as per customers' needs. The price is highly competitive. It is a quality assured product that can be purchased from the company.

Its compact size makes it easy for companies to transport and store. The shot is available in 25kg bags or 40 bags per pallet. The shot is packaged into jumbo and bulk bags depending on their usage and needs. It can be delivered in ten days after ordering. The supplier will provide a sample of the grit to ensure its quality. Its competitive price also means that you can buy a variety of sizes.

Abrasives have been used in blasting applications for centuries. Steel shot has a number of advantages. Compared to traditional grit, this product is highly durable and can be recycled several times. Its low cost makes it very popular and can be reused up to three thousand times. Moreover, the abrasive is environmentally friendly. It can reduce the cost of the process by up to 50%.

S170 steel shot has a small product diameter of 0.5mm and is suitable for use in blast cleaning of castings and other steel products. It is highly durable and has a good cleaning effect. Its moderate hardness and high impact resistance make it an excellent choice for a wide range of uses. If you want to buy cast steel shot, you can contact a reputable supplier in China.

S230 steel shot is used for blast cleaning of metal surfaces. The final finish of the steel shot depends on its size and grade. It is used to produce a smooth and polished surface. Its round shape makes it highly versatile. The rounded shape of the shot allows it to peen a metal surface. This type of steel shot is durable and wear-resistant. It can also be used for heat treatment and profiling.

Product Features of S330 Steel Shot From China

S330 steel shot, which is a kind of high-quality steel shot with high hardness and high sphericity, is mainly used for derusting and polishing.

The Product Features Of S330 Steel Shot:

1.High hardness, high wear resistance.

2.Good elasticity and impact resistance.

3.High sphericity, low crushing rate.

4.Good surface quality.

5.Uniform size distribution, good cleaning effect

Product Features of S280 Steel Shot From China

S280 steel shot is widely used for cleaning iron and steel castings. Its hardness is 40-50HRC, which makes it a good choice for die casting. Its diameter is 0.8mm, and its density is 7.0 g/cc. The company can also customize the hardness and densities according to the requirements of customers. It is highly abrasion resistant and has a long life. The product is also a good choice for shot blasting and die casting.

The angular grit is sharp in the beginning but gradually rounds off in use. It is especially suitable for oxidation skin pre-treatment. The GL steel grit has a higher hardness than GP steel grit, but it loses its edges after the shot basting. The GH steel grot has the highest hardness and is mostly used in compressed air shot blasting equipment.

The hardness of s280 steel shot is 0.8HRC, while that of s660/SS2.5 is 6.5HRC. Both have similar characteristics. Moreover, they have nice microstructure and less consumption. They are widely used in surface cleaning and removing corrosion. The s280 steel shot from China is available in various packaging options, such as 25 kg per bag or 40 bags on a single wooden pallet.

Its high tenacity and hardness make it a great choice for shot peening. It is suitable for blasting applications involving oil, gasoline, and oil. Moreover, it reduces dedusting system load. It is also available in different grades, which are based on the same sae standard. There are many other uses for s280 steel shot. These include:

S280 steel shot from China has the highest carbon content, and its cost is low compared to other sulfate-free, stainless steel and titanium-copper alloys. Despite its high carbon content, it is not very expensive. It is also available in different shapes and sizes, and is widely used for different applications. Among the benefits of this product is its high quality. It is a versatile tool, which can be used in a wide variety of industrial settings.

S280 steel shot from China is available in different specifications and types. The 300 series stainless steel grit is ideal for blast cleaning, while the s280 stainless is more affordable. A wide variety of applications is possible with s280 steel shot, including drilling, machining, and sandblasting. It can also be used in sandblasting to clean and polish nonferrous metal casting parts.

S280 steel shot from China is an excellent choice for use in abrasive blasting. Its purity and quality are internationally recognized and it is made of environmentally friendly materials. A good manufacturer of s280 steel shot from China is able to offer customized sandblasting services and guarantee product excellence. The company also offers quality assurance. It is the best choice for blasting and welding purposes.

Product Features of S110 Steel Shot From China

S110 steel shot is a kind of steel shot with an average diameter of 0.3mm and is produced according to sae standards. The size of steel shot is determined by the processes used to make it. Larger diameters are better for cleaning because of the high cleaning efficiency and the large wear resistance. However, it is important to choose the right size for the workpiece and the material to be cleaned.

S110 steel shot blasting media made of high-quality low-carbon steel, through precision cleaning, scientific composition formula and strict control process.

It has the characteristics of uniform size, good sphericity, high hardness, proper density and low magnetic.

Its hardness is up to HRC40-44 and its density is 7.6g/cm3.

It is widely used in shot blasting machine to derust and clean all kinds of cast iron, steel and other metal products.

Product Features

1. S110 steel shot is the highest hardness of all steel shot, which has the longest using life among all steel shots and can be used more times

2. The hardness of the S110 steel shot is HRC40-50, which is 1% harder than the HRC40-45 S70 steel shot.

3.The size of the s110 steel shot is 0.5mm-1.0mm, which can be used in sandblasting rooms, while the s70 steel shot size range is 0.8mm-1.0mm, which can not be used in sandblasting room.

4.S110 steel shot has a higher density than S70 steel shot, it means that s110 steel shot need less quantity to clean one ton metal surface than s70 steel shots.

5.S110 steek shots are made by a magnetic material, so it can be separated from metal surface easily by magnetism during the process of cleaning metal surface by steek shots

Product Features of S460 Steel Shot From China

S460 steel shot is widely used in the blasting, peening, and casting industries. It is also utilized in the aircraft and gear industries. It is produced as per ISO11124-3 standard. The quality of the product is high, and it has low air-hole content. Moreover, it is produced in accordance with the requirements of the aerospace industry. The s460 steel shot from China is one of the leading brands in the market.

In addition to its high quality, the S460 steel shot from China is an excellent choice for blasting. It is a reliable supplier of quality s460 steel shot from China. This product is certified by the International Bureau of Metals and is widely used in construction, mining, and more. The company's customers can rest assured of the quality of their S460 steel shot from its factory. This company is one of the few Chinese companies with a global presence and an established customer-centric approach.

S460 steel shot is an excellent choice for blasting applications. Its high quality allows it to be used for various applications. It is suitable for many industries. S460 steel shot can also be used in construction projects. Besides, it can be used in the aerospace and automotive industries. The company has been in business for over 10 years. They have a pan-India presence and are a Trade India verified seller.

Product Features of Steel Shot S550 From China

S550 steel shot has a diameter of 1.7mm and has a good cleaning effect. Its uniform hardness and durability make it ideal for many industrial applications. Its toughness and resilience are strong, and it has a high cycle strength. Its durability makes it ideal for the use of concrete cleaners. It is also suitable for various other industrial applications, including steel construction. This product has a long shelf life, making it an excellent choice for concrete cleaners.

The grit is made from high carbon steel, which makes it ideal for sanding and blast cleaning. The grit is extremely hard, which makes it a highly durable option for construction and industrial applications. It can be recycled up to three times, making it a highly-durable and affordable product. Its efficiency allows it to work in a variety of applications and save customers 50% or more.

Steel shot is used for blast cleaning and sand removal from casting and other parts. It is also used in machining, forging, and shot peening. It is a popular choice for blast cleaning steel plates and profiles. And, it is an excellent material for many other applications, including heat treatment and metal finishing. Whether you're a painter or a mechanic, steel shot is a great choice.

When it comes to cleaning metal surfaces, steel shot is one of the best choices. The ultimate finish will depend on the size and grade of the steel shot. Its round shape produces a smooth and polished surface. Through peening action, the shot has compressive strength. Its hardness makes it durable and environmentally friendly. It is a great choice for a variety of applications. This material is also a cost-effective alternative to aluminum abrasives.

The s550 steel shot from China is a high-quality product and is available in a variety of sizes and types. The delivery time is usually 5 to 7 days after you pay the advance. It is also available in a variety of colors, and you can order the right one to match your requirements. You can also choose a different type of steel shot to meet your specific needs.

Moreover, the steel shot from China is available in a variety of sizes. It is available in 25 kg and one-ton bags. It is packaged in a single-ton bag and will take about five days to reach you. It can be delivered anywhere in the world, and if you order it from a reliable supplier, you can be assured of its high quality. The shipping time depends on the size and quantity of the steel shot from the manufacturer.

Steel Shot S780

steel shot s780 is a well-defined grade of shot for use in an industrial foundry, forging plant, heat treatment shop, and steel construction plant. It has been proven useful in the manufacture of locomotives, autos, and containers. Its high strength, tempered Marten site, and 2000 cycles of cast strength make it a versatile product for any application. Its high carbon content makes it ideal for deflashing aluminum die castings.

This type of steel shot is used in abrasive blasting process. It is typically made of a high carbon, low-carbon, and high manganese composition. Because of its higher carbon and manganese content, this grade is more resistant to wear. It also meets SAE hardness specifications as-cast without additional tempering. The company is the only manufacturer of this grade of steel shot in the U.S., and its products are manufactured using the latest technology and methods.

Steel shot has a low friability and is extremely durable. The impact of blasting fuses the steel into a more brittle substance, which keeps repeating the same performance for thousands of cycles. In addition, the steel shot is low-maintenance, which means it can be recycled hundreds of times. The product also provides fast cleaning rates and reduced blasting machine maintenance costs. And because it's so dense, it produces virtually no dust.

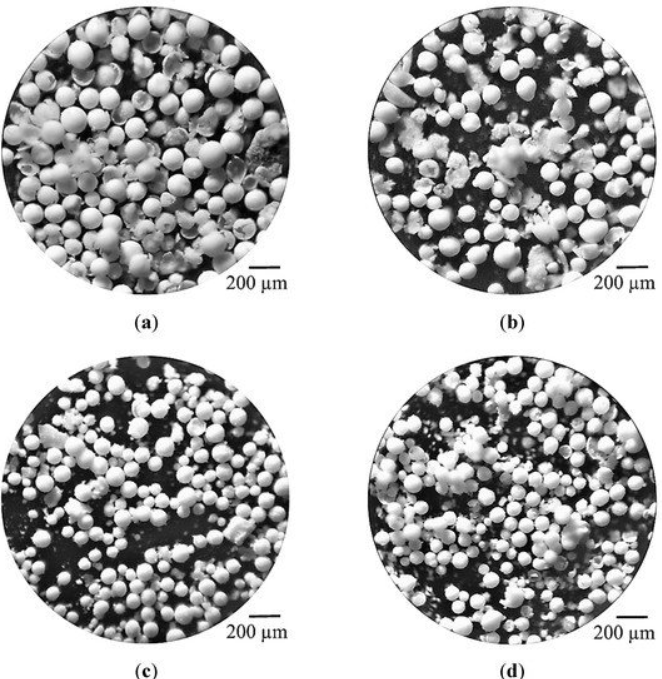

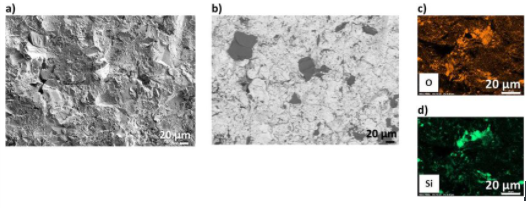

Steel Abrasive - Low Carbon Steel Shot

Low carbon steel shot is a form of shot that is produced from scrap with low carbon content. This type of steel shot has a bainitic microstructure and has no surface cracks. While high carbon steel shot is a form of high-carbon steel with martensitic microstructure and surface cracks, it offers a higher level of hardness and better performance in deburring and surface preparation. The Toscelik Granul low carbon steel shot has a 20% life expectancy than high carbon steel shot and is also easier to handle and uses less energy in processing.

The main benefits of steel shot are its ability to produce a smooth, matte finish and excellent surface profile. Its high-carbon steel composition makes it a cost-effective and recyclable media. The company sells low carbon steel shot to both industrial and institutional users, and offers various sizes and weights. It is used extensively in a variety of industries including the automobile, aircraft, and structural steel industries. It is also suitable for many other industrial applications.

Besides being extremely durable, low carbon steel shot has a low attrition rate. Moreover, its fine particles are uniformly distributed and do not develop surface cracks, which shorten the shot's lifespan. Compared to high carbon steel shot, low carbon steel shot is more economical and environmentally friendly than high carbon steel shot. You can choose from a wide range of sizing options when purchasing high-carbon steel shot.

Steel Shot Beads

Steel shot beads are used for various surface preparation applications. These small steel balls are heated and smooth, providing a uniform, relaxed, and restful surface. Most of these weighted blankets contain a mixture of both glass and steel shot beads, but if you are looking for an alternative, steel shot beads are an excellent option. Most people who purchase weighted blankets don't have any health concerns, but it is a good idea to seek advice from a medical professional before purchasing one.

YALONG's cast steel shot has a high alumina content, and is suitable for use in a blasting booth or a blasting hall. While it is not used for installation, this product is great for cleaning, de-rusting, and roughening applications. There are also other abrasive products available, including Amacast. These are made from chrome steel and don't have a high carbon content, making them a good choice for many different applications.

Steel shot is a versatile abrasive material used in the surface preparation of metals. These balls are round in shape and peen the surface to produce a polished and smooth surface. With their long life and durability, steel shot is a popular choice for these applications. It is also economical, and can be recycled hundreds of times. The size of the steel shot beads used in the blasting process determines the level of clean the metal surface will receive after blasting.

What is Steel Shot Sandblasting ?

Industrial steel shot sandblasting is a vital operation in different stages of primary metal production. The use of different sizes of steel shot produces excellent results on the metal surface. It is an environmentally friendly process and can be recycled hundreds of times. The larger the size of the steel shots, the more thorough the cleaning will be. The shot is accelerated on the surface with a wheel blast system or an air pneumatic system.

Besides removing hard scrapes and burrs, steel shot blasting is also a powerful rust remover. This process efficiently cleans the surface of corroded metal without interfering with the part's integrity. This method is a proven and reliable approach to surface treatment. This article outlines some of its applications and benefits. You can also learn more about this procedure from our guide.

Steel shot is available in many sizes and hardness ratings. It is used to improve metal surfaces. It is also used to remove rust and other unwanted materials. It is also highly economical and effective. The media used in glass bead blasting is recyclable and helps reduce material utilization and waste generation. You can choose the size and hardness of steel shot sandblasting according to the size and shape of the metal part.

What Is Steel Blasting?

Steel blasting is a process that uses steel grit or shot pellets as abrasives to clean metal surfaces. Not only does this method produce a smoother surface finish, but it also strengthens the metal. However, it is important to note that steel grit or shot pellets may not be the best choice for every job. Other materials may be more appropriate for the job at hand. For the best results, make sure to choose the right material and equipment for your project.

In steel blasting, media is typically in the form of steel shot or peening balls, although crush steel alloy grit is also a common choice. Other types of media are synthetic, and made of a polymer matrix filled with silica. Plastic media are more lightweight and less aggressive than ceramic materials, and synthetic steel grit is a common choice. The media used in steel blasting are also very important.

Steel shot or grit blasting are different processes, which are used for different applications. Glass beads are less aggressive, and are best suited for softer materials or thin-walled designs. Using steel shot, on the other hand, is more environmentally friendly than abrasive media like aluminum. In addition to being eco-friendly, shot blasting also speeds up surface prep. Many machines even come with powerful vacuum systems to collect dust.

What Is Steel Abrasive

cast steel shot is a form of grit and is created by streaming molten alloy steel through a water jet. The molten alloy steel atomizes into a series of small particles. The pellets are then dried and tempered. Crushing, screening, and sandblasting processes can also be used to produce cast steel grit or shot. Using these products can be advantageous to the steel industry in many applications.

Cast steel shot is primarily produced by melting scrap metal in an electric induction furnace. The molten metal undergoes a chemical analysis and is then converted into round pellets. The cast steel shot is then quenched and tempered in a subsequent process to increase the hardness of the product. The result is a product with uniform microstructure and hardness. It is then screened to meet SAE specifications for sizing and uniformity.

Cast steel shot is the most popular abrasive for steel parts. It is inexpensive and widely used. However, its low initial cost may limit its use in some applications. Cut wire shot has better performance characteristics and less breakage, which leads to less need for replacement. Stainless steel cut wire shot is an excellent choice for many applications, and is available in high purity grades. It has an even longer cycle life than cast steel shot and produces excellent results. It is the best choice for ferrous contamination and is the cheapest material.

What Is Steel Shot Media

Steel shot is the most commonly used abrasive for metal surfaces. It is used in cleaning, descaling, surface preparation, and shot-peening processes. The final finish of the metal is determined by the grade of steel shot. Its round, ball-shaped shape produces a smooth, clean surface, and the acceleration of the steel shot produces a peening action. There are many different types of steel shots, each of which has its own uses and benefits.

Steel shot is the most common abrasive media used for blasting. It is dense and hard, making it a great choice for many applications. It is safe to use in centrifugal wheel machines, and may be reused multiple times. A company that makes this type of media can also provide you with sample-sized pieces. The media is available in custom-blended Work Mixes, which are pre-mixed with the specific tumbling compound you need.

Steel Shot is available in a variety of sizes and hardness ratings. It is commonly used in steel machining applications to improve the surface of metal. It is also used for cleaning and stripping unwanted materials. The size of the steel shot will determine the final polished finish of the metal part. It is also commonly used in peening processes to harden metal surfaces. The smaller the shots, the more polished and smooth the finished product will be.

What Is Steel Shot Abrasive?

A steel shot is the most common type of abrasive used on metal surfaces. It is used in several processes including cleaning, descaling, surface prep, and shot peening. The grade of steel shot determines the final finish the metal will have. The round shape of the steel shot produces a smooth, clean surface. The accelerated motion of the steel shots creates a peening action.

The next step in the production process is the quenching of steel shots. This process produces high-quality particles with minimal stress cracks. In addition, the blasting process ensures that the steel shot particle is free of microcracks. This results in a more uniform and consistent product. Generally, the finished product is then packaged in bags. Depending on the application, the steel shot can be reused three times before it needs to be replaced.

The process of shot blasting can be used for a variety of applications. It is a cost-effective solution for a wide range of applications. It can be used on a variety of metal surfaces and is safe and environmentally friendly. In addition, it is recyclable and can be recycled. Most manufacturers of steel shot abrasive offer a variety of different grades of this abrasive. They are also available in wheel blasting systems for easy recycling.

What Is Stainless Steel Shot Blasting Media?

Stainless steel shot is often used for surface preparation and finishing. Unlike other materials, such as aluminum, it is not recognized by shot peening specifications. Instead, it is random and angular, which will etch or erode the surface. This type of media is commonly used for the production of high-quality products and components.

Stainless steel shot is different from steel grit. It has a higher concentration of nickel, chromium, and iron than steel grit. It is also available in a wide variety of sizes and hardness. It is better for surfaces that need to be polished but don't want to risk rust stains. Depending on the application, stainless steel shot can be an excellent choice.

Stainless steel shot is another alternative to other media. This abrasive is manufactured by Transmet Corporation, and can be easily recycled. Its high bulk density and angular shape allow it to deliver more energy to parts and prevent them from becoming fractured. Compared to other abrasive materials, stainless steel shot is more durable and can last for hundreds of times. Stainless steel shotblasting media is a versatile choice and it will provide excellent results for any type of project.

Stainless steel shot is a durable abrasive, and it is one of the most widely used processes in cleaning metal surfaces. The final finish of a stainless steel surface depends on the size of the shot and its grade. Generally, a round ball-shaped steel shot produces a smooth, polished surface. Additionally, a round-ball-shaped shot imparts compressive strength to the metal parts.

What Is Steel Shot For Shot Blasting?

Steel shot is the most common abrasive material used for cleaning, descaling, and surface prep on metal surfaces. The grade and shape of steel shots determine the final finish produced on the metal. A round ball shape creates a smooth, clean surface. The peening action is created by the acceleration of the steel shot. This process removes any imperfections and provides a high level of finish for the metal.

Steel shot is a common metallic abrasive that is used for shot blasting. It is often confused with steel grit, but it has a spherical shape and provides a more even finish. Steel grit can be incredibly rough on metal surfaces, and the steel shot has a higher hardness rating. However, it must be used with appropriate equipment to prevent any damage to the metal.

Steel shot comes in a wide variety of sizes and hardness ratings. The smaller the steel shot, the smoother the surface will be. The larger the steel, the more angular it will be. For these reasons, steel shot is used for shot blasting and is the preferred abrasive material. This article will discuss how steel shot is produced and how it benefits you. The information provided will help you choose the right steel shot for your needs.

What Is Stainless Steel Shot Media?

Stainless steel shot is made of abrasive materials. It is used for deburring stampings, peening fabrications, and surface preparation applications. Its characteristics are ideal for removing corrosion and rust. Cast steel shot is used to deflash aluminum die castings. It is an excellent choice for surface preparation, and is available in pre-blended Work Mixes. It is more aggressive than standard stainless steel shot, but is safe to use in centrifugal wheel machines.

Stainless steel shot is a cast form of stainless steel. It can be used in shot peening to create a satin-like finish, leaving the surface clean of contaminants. Stainless steel shot is often used in cleaning non-ferrous castings, such as aluminum. The media can be shaped to produce a smooth surface, and can achieve a high level of finish. It is widely used in the automotive industry.

Stainless steel shot can be used in blasting applications. This media is used for both wheel blasting and air blasting applications. It gives surfaces a sateen finish and can figure-mark objects made of glass. It is recycled, and has a low carbon content, making it an environmentally-friendly choice. It is widely available in standard sizes, and can be reused hundreds of times. Moreover, steel shot blasting is a durable and cost-effective alternative to traditional methods of cleaning.

Steel Abrasive - What Is Stainless Steel Cut Wire Shot?

Stainless steel cut wire shot is a specialty of stainless steel that is becoming increasingly popular for peening non-ferrous metals. Unlike cast steel shot, which can contain ferrous contamination, stainless steel cut wire shot is made entirely from stainless-steel wire. Using special machines to produce the product, the wire is conditioned for use in shot peening. Its Rockwell hardness ranges from 50 to 58 HRC and is available in a variety of diameters.

Stainless steel cut wire shot is manufactured from 300-series stainless steel and has a bulk density of 4.5 kg/l. It is ideal for cleaning and smoothing surfaces after blasting. The product is also non-corrosive, which is a key factor for many applications. Its high density makes it an excellent choice for peening and blasting low-hardness components. It is easy to handle and can be used to make parts without damaging the material.

Stainless steel cut wire shot is a great choice for abrasive blast cleaning of non-ferrous parts. Its low hardness makes it resistant to impact and abrasive wear and increases component life. The product is packaged in 25-kg HDPE double-bags for easy handling. These products are also ideal for descaling and deburring. This material is ideal for a variety of applications, including steel fabrication.

What Is Stainless Steel Grit?

Stainless Steel Grit is an abrasive that is ideal for cleaning heavy rust and heavy coatings. Because of its angular shape, Stainless Steel Grit is less likely to break apart when striking the surface. It also has a long usable life. Because it is dust-free, it is also a good choice for environmentally conscious organizations and businesses. Stainless Steel Grit is available in bags of 55 pounds.

Stainless Steel Grit is produced by crushing Cr-stainless steel into angular particles. Compared to other abrasive media, it is safe and stable for use in industrial settings. Although it requires no special handling or storage conditions, it is important to wear personal protection equipment. It should never come into contact with eyes or skin. As with any abrasive, this material should be stored in a well-ventilated area.

The most common type of stainless steel finish is called No. 4. It is used on food-grade appliances and in the food industry. This finish has short parallel polishing lines that are visible after welding. The process is repeated with finer abrasives, resulting in a surface that is more reflective and resistant to water. The higher the grit, the more reflective the surface will be.

What Is Stainless Steel Shots?

If you're looking to burnish metals to a mirror finish, you've probably wondered what is stainless steel shots. Stainless steel requires cleaning only occasionally but provides a beautiful uniformity. It is available in three different shapes, each of which has a specific job in burnishing metals to a mirror finish. Most applications use a combination of three different shapes. The only disadvantage of stainless steel is the maintenance required.

Stainless steel shot comes in a variety of shapes. A typical shot consists of one kilos of mixed steel that is suitable for tumbling. The mixed shot contains balls, planetoids, and large pins. The pins are sharp and will eventually dull. Premium stainless steel shot does not include pins. It is best to use a shot that does not have sharp points. A good quality shot is hard, dense, and produces little dust.

Stainless steel shot is a grain size product that is ideal for non-rusting materials like stainless steel. The small grain size of stainless steel makes it ideal for cleaning, deburring, hardening, and surface finishing. While ferritic dust can discolor a bright surface, stainless steel shot can make your piece look polished. This product is also very easy to maintain and comes in 2.2 pound containers. It is easy to clean and dries, and will last for years.

What Is Stainless Shot?

A common question is what is stainless shot? It is the term used to describe a variety of materials used to burnish and polish metals. Stainless steel is extremely uniform, which makes cleaning it necessary only once or twice a year. Jeweler's Mix is one type of highly polished stainless steel shot mixture. It is composed of three shapes, each of which does a different job when burnishing metals to a mirror finish. This is the only type of shot mixture that is appropriate for most applications.

Stainless steel shot is a type of metal shot that is largely used for surface preparation and finishing. Stainless steel is a very common material used for shot blasting and is used to clean non-ferrous metals as well. While stainless steel can be oxidized with time, it is more prone to corrosion than other metals. Regardless of the purpose, stainless steel shot is a versatile material that can be used to add a professional shine to any project.

Stainless steel shot blasting can be used to remove surface contaminants that cause rust. The product also helps reduce smears and scratches. The product comes in 2.2-pound containers. Unlike carbon steel media, stainless steel shot blasting is more effective than sandblasting, which can damage the surface of the finished piece. The process is much faster than conventional methods and is more affordable. To get started, contact a stainless steel blasting company.

What Is Round Stainless Steel Shot?

Stainless steel shot is a form of abrasive that is used in various processes. It is a widely used abrasive in sandblasting and shot peening machines. Stainless steel shot can be recycled up to three times before it needs replacement. Stainless steel is highly resistant to corrosion and is therefore an ideal choice for use in a wide variety of applications. For more information, read on:

Stainless steel shot is a form of abrasive media. It is used for polishing, cleaning and surface preparation. The smaller the steel shot, the smoother and finer the finished product. The great thing about this abrasive is that it can be used again, making it an eco-friendly choice. This material is also often cheaper than other abrasive media and is therefore more affordable.

Cast steel shot is the most common type of abrasive and is typically used in pass through and tumble blast machines. Cut wire shot is an excellent alternative to cast steel shot because it is more durable, has a higher cycle life, and has less breakdown. Stainless steel cut wire shot is also a good choice when corrosion is an issue. It is also available in larger sizes and is extremely durable. It is also environmentally friendly, as it can be recycled hundreds of times.

Stainless steel shot is one of the best options for finishing stainless steel. It can be easily purchased at any hardware store and is a great choice for a variety of applications. From paint removal to removing light scale, it can remove virtually all types of contaminants. It also improves the appearance of stainless steel surfaces. It is a proven and reliable surface treatment for various metal types. This material is made from high quality material and will add a beautiful finish to any piece of metal.

What Is Stainless Steel Shot Balls?

Stainless steel shot balls are made of hardened, tempered stainless steel. They have a uniform burnishing action and are ideal for parts that need high reflectivity and a fine finish. The softer steel is not suitable for applications requiring high reflectivity. They can be used for high-impact applications, but should not be placed in water or submerged in saltwater. The corrosion-resistant stainless material minimizes handling and storage costs.

Stainless steel shot is generally used in finishing processes, surface preparation, and metal cleaning. In many applications, stainless steel shot is the best choice for peening applications, as it produces a smooth finish. It is also recyclable and generates very little dust. Among its other benefits, it is highly resistant to atmospheric corrosion, is dense and hard, and is very resistant to food and other organic materials. This is why it is so popular in various industries and is used for various applications.

Stainless steel shot is perfect for cleaning, deburring, hardening, and surface finishing. Its high grain size makes it the ideal shot for these applications. Compared to ferritic dust, stainless steel shot is free from any contaminants and discolors bright surfaces. Furthermore, it is compact, which means it can last longer and perform better without wearing out the machine. The low carbon content of the stainless steel balls makes them ideal for low-speed applications.

What Is Stainless Steel Cut Wire?

Stainless steel cut wire is a variety of abrasive tools. Its use ranges from peening to cleaning. Its consistent size and shape make it the ideal material for peening applications. Stainless steel cut wire is also very hard and offers dust-free results. It is available in three different types - as-cut, partially conditioned, and fully-conditioned. For these purposes, it is a popular choice among casters.

The most popular type of stainless steel cut wire is made of 300 series stainless steel. It is characterized by a high density and bulk density of 4.5 kg/l. Compared to carbon wire, stainless cut wire is extremely strong. This material is often used in peening applications. It does not fracture or delaminate as it wears. Zinc cut wire is an environmentally-friendly material that is perfect for cleaning fixtures and removing paint hooks.

Stainless steel cut wire is a specialty shot that is manufactured to rigid specifications. It is typically conditioned or "as-cut" depending on its application. It is also available in a special ferrous-free form that is safe to handle. Carbon-free stainless steel cut wire is a good choice for peening non-ferrous materials. It does not fracture and delaminates. A zinc-coated version is ideal for stripping paint hooks or cleaning fixtures.

What is Steel Cut Wire?

Steel cut wire is a material that is made by cutting carbon steel wire into pieces of equal diameter. The chemical composition allows it to have a high traction resistance. It is different from cast steel shot and other types of abrasives. The steel cut wire is created from materials with the same grain size and chemical-physical properties but are free from impurities. It is produced using a special production system that avoids grains with inclusions, cavities, blowholes, cracks, and other impurities.

The most common form of cut wire is stainless steel. This metal has a high level of resistance to corrosion. It is often used in chemical plants and construction sites. It is available in both conditioned and unconditioned forms. Stainless steel cut wire is available in different diameters. The stainless steel wire is also available in a variety of forms. You can purchase As Cut, Partially Conditioned, or Full Conditioned.

Stainless steel cut wire is manufactured to very rigid specifications, which makes it an excellent choice for harsh applications. It is available in both "as cut" and "conditioned" forms. Carbon cut wire is perfect for peening and is free of delamination and fracture. Zinc cut wire is best for cleaning fixtures and stripping paint hooks. Abrasive blasting is another common use for carbon steel cut wire.

Telephone :+86 157 6285 8378

Telephone :+86 157 6285 8378 WhatsApp :+86 157 6285 8378

WhatsApp :+86 157 6285 8378 Email :info@ziboyalong.com

Email :info@ziboyalong.com