How Much Grit Do I Use For Steel Polishing?

How Much Grit Do I Use For Steel Polishing?

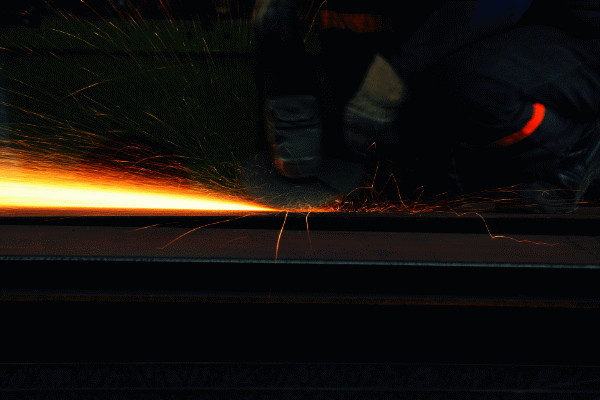

A common question in the steel polishing industry is: How much grit do I use? Stainless steel can be difficult to work with, but it has a beautiful, fine appearance. The first step is to use a coarse abrasive to remove scratch patterns and roughen the surface. You can then move to finer abrasives to smooth out the scratches and improve the finish. Depending on the size of your project and the desired finish, you may have to use multiple grit sequences.

The grit you use will depend on the type of metal and its condition. If the metal is too rough, use coarse grit sandpaper. The next step is to use finer sandpaper around 80 or 100 g. After that, repeat the process with a finer sandpaper, around 160 or 200 g.

The coarse grit sandpaper should be used to polish the metal. The grit should be used when the metal is too rough to be polished. It is best to start with coarse sandpaper and move up a few sandpapers until the surface is smooth. Once the surface is smooth, move on to the next sandpaper. Remember to clean your parts after each pass!

When polishing metal, use finer sandpaper. For example, 320 grit is used to polish steel and stainless steel. If you want a slick finish, use 1,200 grit. It depends on the type of finish you want to achieve. Once you've made up your mind, it's time to get to work! You can also try a few different grits until you find the one that suits your needs.

The grit size is another important factor. In general, the finer the grit, the more fine particles will remain. The coarser abrasive will not cause any scratches, and the finer abrasive will give you a smoother finish. To avoid scratches on the steel, you should use a wet abrasive polishing solution.

When polishing stainless steel, choosing the right grit size for the job is important. The grit number is the most common unit for coarser sandpaper. It is derived from the mesh size. The higher the mesh size, the more finely the grit is. However, it's always best to read the sizing information on the packaging of the steel sandpaper.

In addition to the fine grit, it's also important to know how to use the coarse grit for the steel polishing process. If the metal is too rough, fine sandpaper will work better. If it's too rough, it will create too many scratches. If you're trying to polish stainless steel, you can go up to two levels of grit.

The grit of sandpaper is essential for the process of polishing. For example, 320 grit is best for rougher sanding. If you're polishing a stainless steel part, you should use the grit of high-quality sandpaper with a high grit. A sandpaper with a higher granularity is better for a more delicate finish.

To polish stainless steel, you'll need a higher grit than you'd need for a regular steel polish. A 320 grit sandpaper is sufficient for a light polish. A 320 grit abrasive will work well for a brushed finish. Ultimately, the higher a sandpaper's resiliency to scratches, the better.

Choosing the right grit for a particular application is critical. Good sandpaper will not damage apiece, but it will make the process faster and more efficient. Using the correct sandpaper will ensure a quality finish. To get a flawless finish, you must spend time polishing and not rush. Often, the best finish comes with patience and perseverance.

Telephone :+86 157 6285 8378

Telephone :+86 157 6285 8378 WhatsApp :+86 157 6285 8378

WhatsApp :+86 157 6285 8378 Email :info@ziboyalong.com

Email :info@ziboyalong.com