S110 Steel Shot: The Ultimate Guide to Faqs

S110 Steel Shot: The Ultimate Guide to Faqs

High carbon cut wire shot is made by cutting spring steel wire into lengths that are equal to the diameter. A high carbon shot is softer and creates less dust than aluminum oxide. Both types have many benefits. ERVIN uses the thermal treatment process to produce s110 steel shot. This is a very useful shot in a variety of applications. Read on to learn more about this shot. It is a high-quality shot made from stainless steel cut wire.

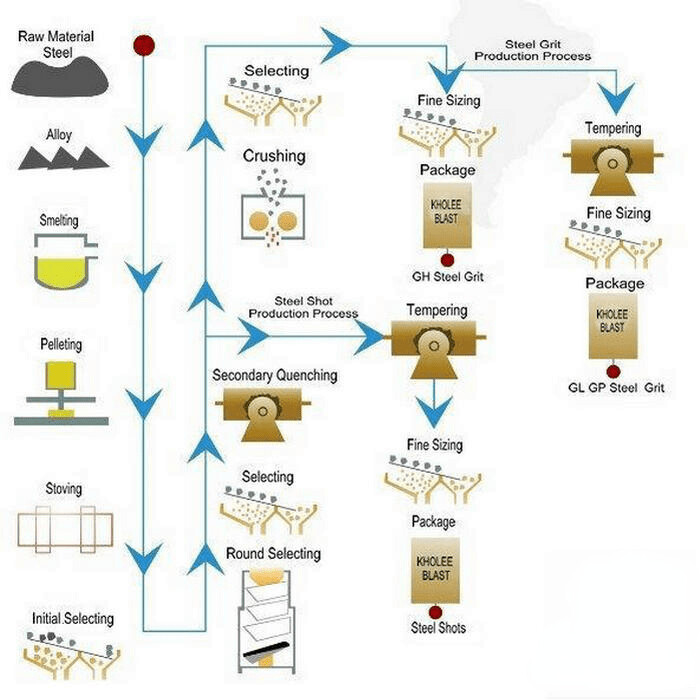

YALONG's thermal treatment process produces s110 steel shot

The thermal treatment process improves the performance of s110 steel shot. The process refines its microstructure, improving resistance to wear and failure. The resulting material is highly effective and durable while delivering the lowest cost of production and consumption. Designed for industrial foundry, forging plant, steel construction plant, and container, ship, and auto manufacturers, s110 steel shot offers superior performance and versatility.

The impact of shot 26 increases the surface temperature of the metal shot material 29. The iron-containing shot material raises the temperature above the A3 transformation temperature. The increase in temperature is localized to the surface layer, and the material cools rapidly after impact. This allows for the production of s110 steel shot of high quality, strength, and corrosion resistance. In contrast, nonferrous metal shot material is more brittle and cannot be thermally treated.

yalong's thermal treatment process for s110 steel shot yields the finest particles in the industry. Its superior ballistic properties enable it to be used in the most demanding applications. Its spheroidal composition helps to prevent fuzzing and enhances its ballistic properties. A spherical grain structure produces s110 steel shot that is ideally suited for a variety of applications.

High carbon cut wire shot is made by cutting spring steel wire to lengths equal to the wire diameter

A high carbon cut-wire shot is produced by cutting spring steel wire to lengths equal in diameter to the final product. The chemical and physical properties of spring steel wire, as well as its accurate cutting to length, determine the quality of the cut-wire shot. This high-carbon shot is spherical in shape and available in many different sizes. Its applications include shot peening, cleaning, and smoothing.

The depth of the high carbon cut-wire-shot is determined by the length of the corresponding lengths in spring steel wire. It is the depth that corresponds to the area of maximal combined stress. The greater the compressive residual stress, the greater the fatigue resistance. The -sR0.2 and -sR0.4 index values are 100 MPa or higher.

The diameter of a high-carbon cut-wire shot is determined by a combination of factors, including the hardness of the wire material, the particle diameter, and the rate of injection. The diameter of a high-carbon cut-wire shot should not exceed 20 mm. The amount of time spent shot peening determines the level of residual stress distribution. It should be injected with a rate that is equal to or smaller than the wire diameter.

The use of a cut-wire steel shot improves the performance of the shot-peening process. It refines the microstructure and increases resistance to wear and failure. The low cost of production and consumption makes it the preferred shot for peening applications. In addition to its superior performance, the cut-wire steel shot is compatible with stainless steel. A typical shot of cut-wire steel shot will cost between 1.5 and four kg.

It is softer than aluminum oxide

S110 steel shot is a widely used type of shot that is softer than aluminum oxide. This type of steel shot has grain sizes that are 0.3mm or larger. Large grain sizes make the shot easier to clean and more durable. The steel shot is made of low-carbon steel and goes through rigorous quality control procedures. The shot has good hardness and low magnetic properties. It is available in different colors for varied applications.

This type of steel shot has high compressive strength and is commonly used in machining processes, such as in the fabrication of shotgun shells. It is also used for cleaning and stripping unwanted materials from metal parts. The smaller diameter of this type of steel shot will produce smoother metal parts. It also has a higher bonding ability with paint. S110 steel shot is available from reliable suppliers in China.

S110 steel shot is a great option for cleaning metal surfaces. Unlike aluminum oxide, steel shot will not fracture under direct pressure. Unlike aluminum oxide, it does not degrade or disintegrate easily, making it the perfect choice for airless blasting. This softer metal shot can withstand hundreds of impacts, while aluminum oxide only lasts for a single impact. For this reason, steel shot is preferred for surface blast cleaning.

It produces less dust than aluminum oxide

The abrasive properties of stainless steel cut wire shot make it an excellent choice for cleaning non-ferrous metal surfaces. Compared to aluminum oxide, stainless steel shot has lower abrasive properties and is ideal for roughening, cleaning, and de-rusting metal surfaces. It is available in two-bag 25-kg HDPE packages. Here are some reasons why steel shot is a better choice for cleaning.

S110 steel shot produces less dust than aluminum dioxide and has a small product diameter of 0.3mm. It has a high cleaning efficiency and high wear resistance, making it an excellent choice for a variety of applications. Whether used in automotive applications or industrial settings, S110 steel shot from China is widely available and affordable. It is available in different shapes and sizes and is made of low-carbon steel with a scientific composition formula and rigorous quality control. Its density is 7.6g/cm3.

As steel shot is low-friability, it is durable. It can be recycled hundreds of times and is easy to use. It is also low-maintenance, reducing maintenance costs and allowing for fast cleaning rates. And, unlike aluminum oxide, it produces virtually no dust. In addition to these benefits, a steel shot is ideal for cleaning concrete surfaces and other metal surfaces. It also helps remove adhesives, rubber build-up, and epoxy.

It is used for shot peening of ferrous materials

S110 steel shot is used in a wide range of applications, including shot peening of ferrous materials. Unlike aluminum oxide, S110 is softer than the former and does not fracture as easily. Unlike aluminum oxide, S110 can be used in a variety of direct-pressure applications, including shot peening of ferrous materials. These metallic abrasives are also great for airless blasting applications, as they have an extended life.

S110 steel shot is a high-carbon precision metal. It is available in cast steel and stainless steel cut wire. It is a relatively low-cost material that offers optimum resilience and resistance to fatigue. It is widely used for shot peening ferrous materials in the steel construction industry, as well as in auto and locomotive manufacturing. Steel shot is an effective and efficient surface treatment for many different materials.

The process of shot peening involves propelling metallic shots against metal surfaces. These shots hit at high velocity and act as tiny "peen-hammers" that dimple and stretch the metal surface. When these shots are struck, they cause flow of fibers in the surface to the depth of the impact. The fibers beneath the surface layer retain elasticity, making shot peened surfaces less likely to fracture under heavy loads.

It is sold in 55lb bags

S110 steel shot is a popular type of blasting media available in bags of 55 pounds. It comes in various colors and sizes and is manufactured in China. The steel shot is inexpensive and readily available and offers excellent results on metal surfaces. It is sold in bags for ease of use and is shipped anywhere in the world in ten days. For the most competitive prices, S110 steel shot is often a good choice.

The grain size of S110 steel shot varies based on the process used to produce it. A larger diameter steel shot will have higher surface roughness after cleaning. This shot is more effective and efficient, but it also has a higher rate of wear. You should compare the grain size of S110 steel shot sold in different manufacturers before choosing one to use in your work. Here are a few of the benefits of the S110 steel shot:

The S110 steel shot is a hard, rounded media used in surface blasting. It is able to withstand hundreds of impacts, unlike sand blasting machines, which are capable of only one impact. In addition, it is environmentally friendly and durable, meaning that the shot you buy can last for a long time. It is also a cost-effective way to finish a project.

Telephone :+86 157 6285 8378

Telephone :+86 157 6285 8378 WhatsApp :+86 157 6285 8378

WhatsApp :+86 157 6285 8378 Email :info@ziboyalong.com

Email :info@ziboyalong.com