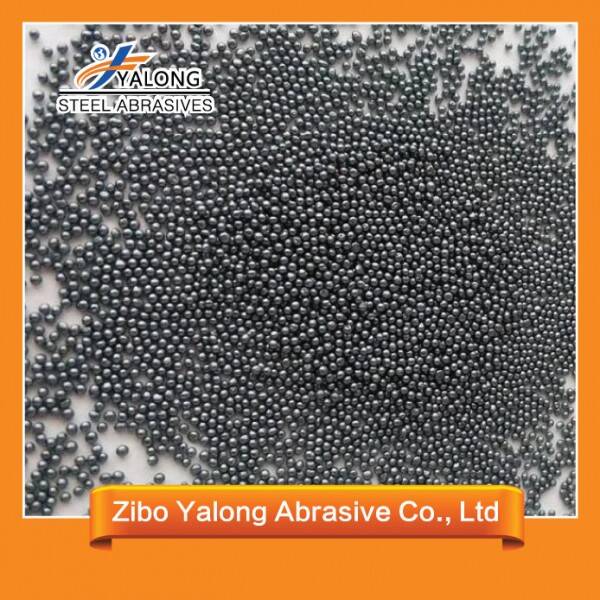

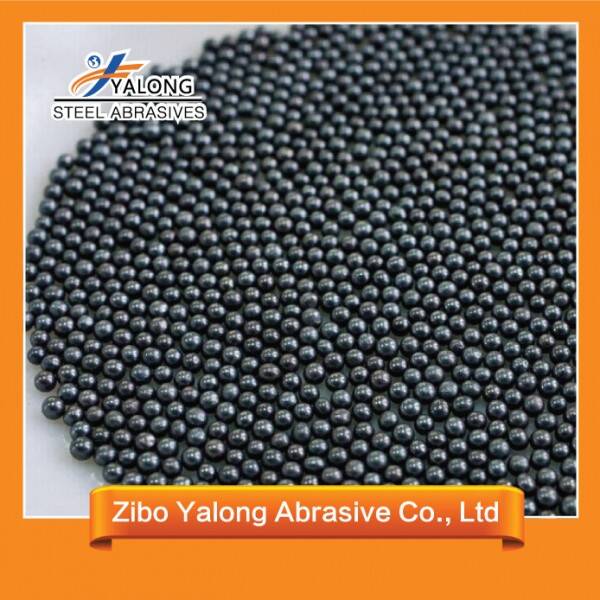

S230 steel shot Hardness 30~45HRC Stainless Steel Shot, 0.2-2.0mm Steel Shot For Aircraft

We have our own in-house quality control system. Chemical component analysis, Hardness testing, Density Testing, Fatigue life testing all available. We are serious and strict for the quality control of our abrasives.

Also we have good cooperation with SGS Qingdao branch, more testing available if you need, such as Abrasive Conductivity Testing.

S230 steel shot Hardness 30~45HRC Stainless Steel Shot, 0.2-2.0mm Steel Shot For Aircraft Specifications :

| Price | Contact Us |

| Place of Origin | Shandong, China |

| Payment Terms | T/T, L/C, Western Union, etc. |

| Delivery Detail | 10-25 Working Days. |

| Keyword | Steel Shot Beads |

S230 steel shot Hardness 30~45HRC Stainless Steel Shot, 0.2-2.0mm Steel Shot For Aircraft Detail Introduction :

s230 steel shot

S230 steel shot is a high-hardness steel shot with a diameter of 0.6mm, widely used for abrasive blast cleaning. Its uniform hardness and microstructure enable fast cleaning rates and excellent brightness. It can be used in various blasting equipment, such as in sand rooms and steel plate pretreatment production lines.

High Carbon Steel shot are produced by atomization of molten steel followed by a series of thermal and mechanical treatments.

Centrifugalizing process instead of high water jet streams to atomize the liquid steel into more spherical and uniform particles.

Durable with high resistance to impact fatigue, giving it an effective and quick cleaning rate.

The centrifugal atomization process and double heat treatment, as well as continuous quality control measures, ensure the shot is of the highest quality.

Product | STEEL GRIT STEEL SHOT | Type No. | STEEL GRIT GH/GL/GP10-120 STEEL SHOT S070-S1110 | |

Test Items | Specifications | |||

STEEL GRIT | STEEL SHOT | |||

Chemical Composition % | C | 0.85-1.20 | 0.85-1.20 | |

Mn | 0.40-1.20 | 0.40-1.20 | ||

Si | 0.40-1.20 | 0.40-1.20 | ||

S | ≤0.05 | ≤0.05 | ||

P | ≤0.05 | ≤0.05 | ||

Hardness ( HRC ) | 60-66(GH) 50-60(GL) 42-50(GP) | 40-50 | ||

Metallographic Structure | Even-tempered martensite | Even-tempered martensite | ||

Telephone :+86 157 6285 8378

Telephone :+86 157 6285 8378 WhatsApp :+86 157 6285 8378

WhatsApp :+86 157 6285 8378 Email :

Email :