0.2-2.8mm Sphere Conditioned Cut Wire Shot, Steel Cut Wire Shot For Blasting Machine Application

We have our own in-house quality control system. Chemical component analysis, Hardness testing, Density Testing, Fatigue life testing all available. We are serious and strict for the quality control of our abrasives.

Also we have good cooperation with SGS Qingdao branch, more testing available if you need, such as Abrasive Conductivity Testing.

0.2-2.8mm Sphere Conditioned Cut Wire Shot, Steel Cut Wire Shot For Blasting Machine Application Specifications :

| Price | Contact Us |

| Place of Origin | Shandong, China |

| Payment Terms | T/T, L/C, Western Union, etc. |

| Delivery Detail | 10-25 Working Days. |

| Keyword | Cut Wire Shot |

0.2-2.8mm Sphere Conditioned Cut Wire Shot, Steel Cut Wire Shot For Blasting Machine Application Detail Introduction :

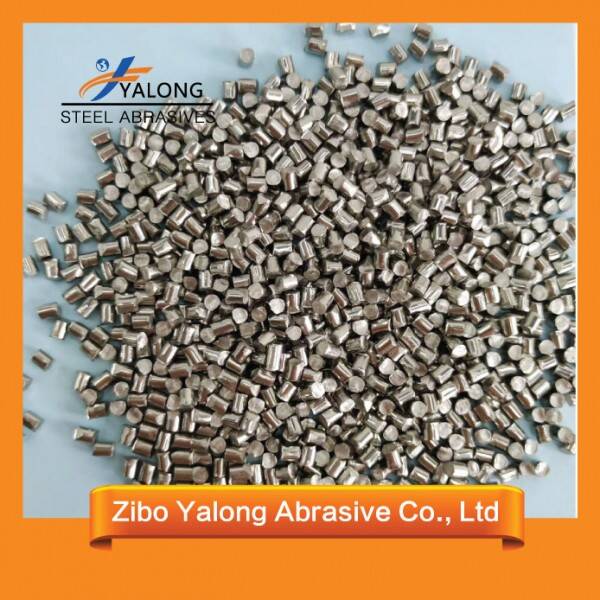

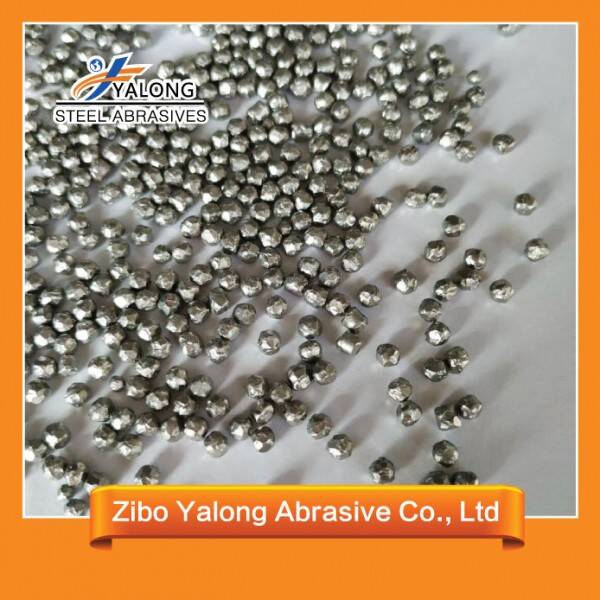

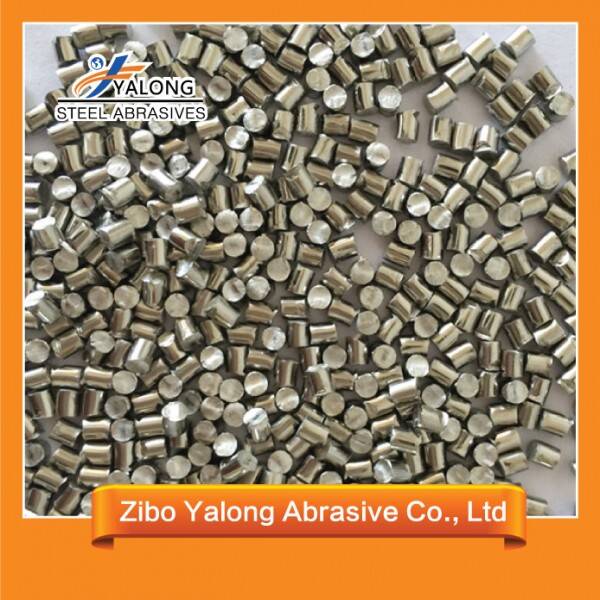

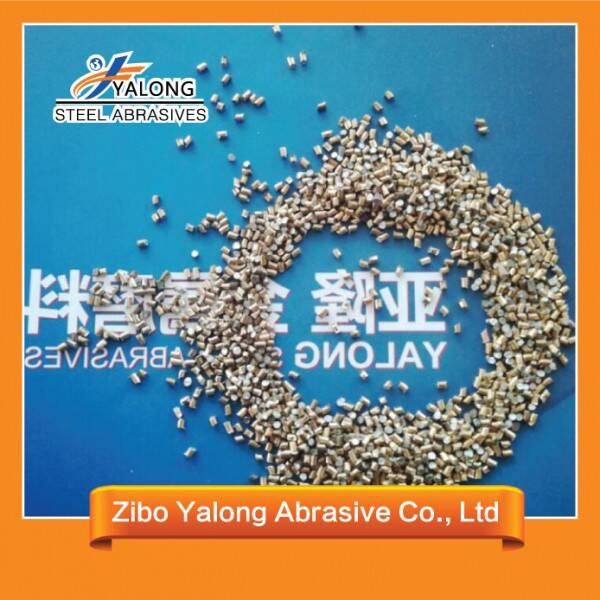

Steel Cut Wire Shot

High Carbon Steel Cut Wire Shot as per AMS 2431/8B.

These wire shots are formed by cutting wire into lengths equal to wire diameter.

These are particularly used for peening applications where a higher level of abrasive hardness is desirable.

Strict Quality Control procedures are required to be able to manufacture cut wire

shot meeting all common industry specifications as well as many individual customer specifications.

Different levels of conditioning.

CW – As Cut

G1 – Single Conditioned

G2 – Double conditioned

G3 – Spherically conditioned

Size: 0.3 – 3.0 mm

Hardness: 40-60 HRC

Test Items | Specifications | |

CHEMICAL COMPOSITION% | C | 0.45-0.80 |

Mn | 0.40-1.20 | |

Si | 0.10-0.30 | |

S | ≤0.05 | |

P | ≤0.05 | |

PHYSICAL PROPERTIES | Hardness of each Grade ( HRC ) | 40-60 |

Metallographic Structure | Even tempered martensite | |

Telephone :+86 157 6285 8378

Telephone :+86 157 6285 8378 WhatsApp :+86 157 6285 8378

WhatsApp :+86 157 6285 8378 Email :

Email :