The Benefits of S230 Steel Shot

The Benefits of S230 Steel Shot

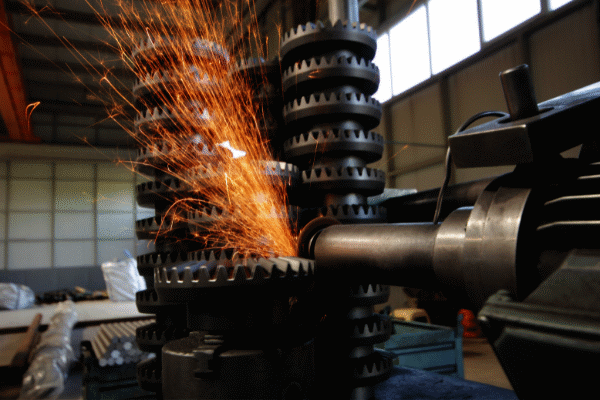

S230 steel shot is widely used for steel structure pretreatment. It is a small diameter product with good abrasion resistance. Its uniform hardness, high resilience, and good adhesion enable excellent coverage rates. Its high impact resistance, toughness, and wear resistance make it a perfect choice for the pretreatment of steel structures. This type of shot is suitable for various types of shot blasting equipment. The following are the benefits of the S230 steel shot.

S230 steel shot is most commonly used for peening and blast cleaning applications.

The round ball shape of the S230 shot prevents wear to machinery. It is widely used for sand cleaning castings. It is a valuable abrasive for surface cleaning. It is used in the automotive, aerospace, and container industries. It is also used for shipbuilding and consumer goods manufacturing. Its versatility makes it an excellent choice for a range of applications.

S230 steel shot is a versatile tool for many applications.

It is produced using high-quality steel blocks, wool, and a proprietary process. The molten steel is shaped into a sharp ball and cooled in water. Once the shot has cooled, it is quenched, dried, and reheated. Once it cools and becomes soft, it is then tempered in a furnace. The tempered steel shot is then sorted into different grades following SAE standards. The heat treatment of the S230 steel shot allows it to exhibit the highest elasticity and fatigue resistance of any of the rates. For blast peening, S230 steel is available in various grit sizes.

S230 steel shot is an excellent choice for blast cleaning applications.

It is ideal for applications where a complex workpiece is to be treated. S170 steel shot has an average Dave of 0.58 mm, whereas S230 steel shot has an average diameter of 0.504. Despite the difference in size and diameter, the advantages of the S230 steel shot include high cleaning speed and good rebound. The steel shot is also effective for dusting, flat strengthening, and derusting.

The essential advantages of the S230 steel shot include its high cleaning speed, appropriate hardness, and high rebound. These characteristics make this steel shot a perfect choice for deburring applications. It also offers the highest efficiency in blast cleaning. The ABSS CS1000 Suction Blast Cabinet supports a 2000cfm Ventilation Dust Collector and has impressive power. This model provides a fast and efficient solution for manufacturing aluminum housings.

S230 steel shot is an excellent choice for deburring and sandblasting applications.

Its high hardness and high rebound enable it to remove oxidation on steel. It is the most efficient abrasive in this class of application. It can also be used in high-speed welding applications, reducing the need for chemical cleaning. This product is used by professionals in shipbuilding, consumer goods manufacturing, and the aerospace industry.

Premium S230 steel shot is a popular choice for deburring applications.

Its high hardness and small size make it an excellent choice for deburring. It is also a perfect choice for peening applications in the foundry and aerospace industries. Its low cost and ease of use make it an ideal choice for sandblasting. The S230 steel shot is an effective abrasive for surface cleaning.

S230 steel shot has a low melting point and is used for blast cleaning.

Its melting point is around 320°C. The S230 steel shot is also an excellent option for peening applications. These shots can be used in the ABSS CS1000 Suction Blast Cabinet. S230 steel shot is a high-quality product ideal for many different types of applications. There are many benefits to this steel shot, and you should consider its advantages over other types of peening media.

S230 steel shot is a durable and affordable material.

Its high elasticity makes it suitable for a variety of peening applications. The material is produced from high-quality steel blocks and wool. The process is known as shot peening. The resulting steel is a bluish-gray alloy that can withstand various load forces. Its elongation and hardness make it an ideal choice for steel rim-making.

Telephone :+86 157 6285 8378

Telephone :+86 157 6285 8378 WhatsApp :+86 157 6285 8378

WhatsApp :+86 157 6285 8378 Email :info@ziboyalong.com

Email :info@ziboyalong.com