What Is the Grit Equivalent of Steel Wool?

What Is the Grit Equivalent of Steel Wool?

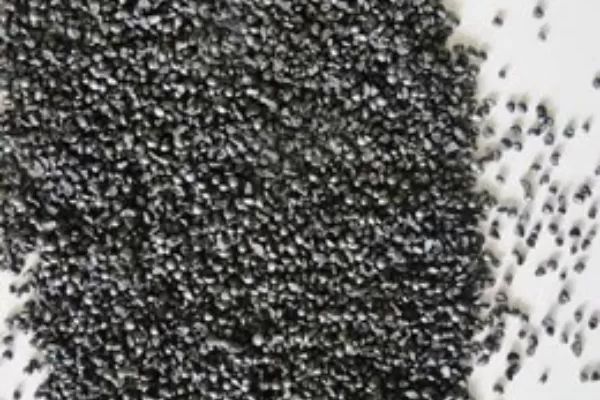

There are several kinds of abrasives, but steel wool is the most common and often recommended. Its very fine strands can effectively remove an ultra-thin layer without damaging the surface underneath. In addition, steel wool can be used in hard-to-reach places and on complex shapes. This article will explain the difference between steel and sandpaper and how to use each type of abrasive.

Fine metal wools can be used to produce a smoother finish after sanding or polishing. They can also be used to polish fine wood articles and glass. The grit equivalents of steel wool are similar to those of sandpaper, with 0000 being the finest and 4/0 the coarsest. The most popular grades are Green Scotch Brite (600 grit) and Blue Scotch-Brite (1000 g).

When used properly, steel wool can eliminate the need for a chemical. It can be used on surfaces as soft as glass, and it is effective for cleaning, polishing, and scrubbing. However, it should not be used on surfaces that are water-based, such as paint. Additionally, steel wool will cause rust stains to appear on the surface. It is also not recommended to use steel-wool on plaster, because small pieces may become trapped and rust. If these pieces are stuck, they can be removed using a soft cloth or with the help of a strong magnet.

The gray-colored pad is the equivalent of 000 steel wool. The white pad contains talc and is used for polishing. This steel wool has a low ash content and is also more durable than aluminum oxide. Unlike steel-wool, aluminum oxide is more expensive and can only be reused 150 or 200 times. It can dull sharp details, so it is an ideal choice for many applications.

Unlike steel wool, aluminum oxide is not porous. It is a nonwoven synthetic fiber pad impregnated with abrasive particles. Unlike steel-wool, it rides over high spots, and is more abrasive. The material is commonly used after wet-sanding. It is usually used with lubricant. If you are working on wood with a finish, you can use synthetic steel wool instead.

While steel wool is the grit equivalent of steel wool, it's important to know that its abrasive properties are different. The difference between steel wool sandpaper has a high abrasive density. Consequently, the two types of sandpaper are similar, but differ in their grit sizes. Using both types of steel grit can be beneficial to your project.

Telephone :+86 157 6285 8378

Telephone :+86 157 6285 8378 WhatsApp :+86 157 6285 8378

WhatsApp :+86 157 6285 8378 Email :

Email :