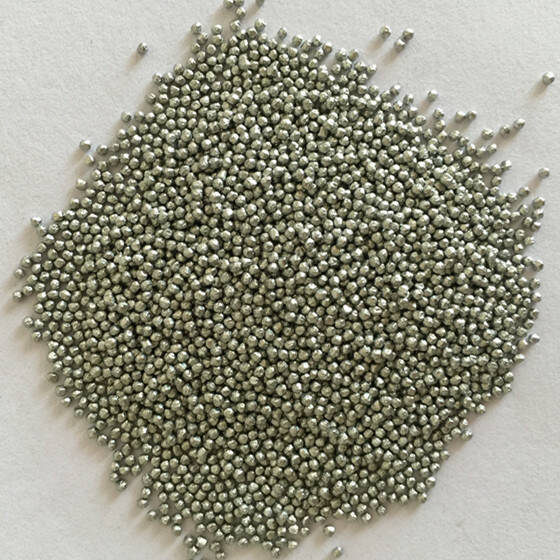

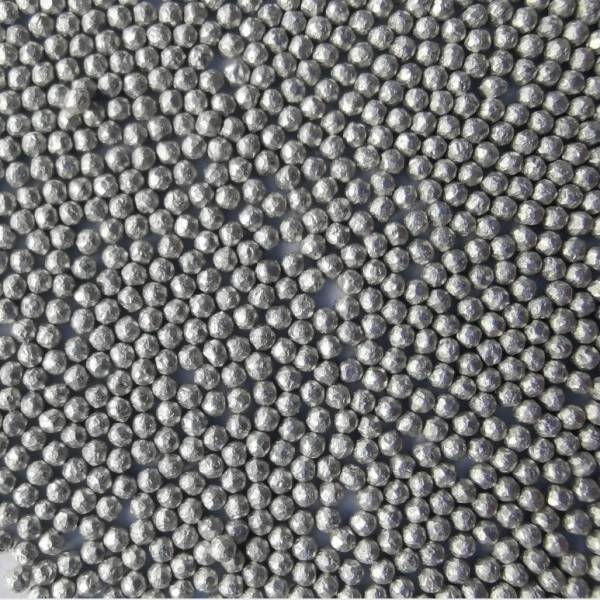

Silvery White Zinc Cut Wire Shot - As Cut Or Conditioned For Polishing, Derusting, Surface Cleaning

We have our own in-house quality control system. Chemical component analysis, Hardness testing, Density Testing, Fatigue life testing all available. We are serious and strict for the quality control of our abrasives.

Also we have good cooperation with SGS Qingdao branch, more testing available if you need, such as Abrasive Conductivity Testing.

Silvery White Zinc Cut Wire Shot - As Cut Or Conditioned For Polishing, Derusting, Surface Cleaning Specifications :

| Price | Contact Us |

| Place of Origin | Shandong, China |

| Payment Terms | T/T, L/C, Western Union, etc. |

| Delivery Detail | 10-25 Working Days. |

| Keyword | Zinc Shot |

Silvery White Zinc Cut Wire Shot - As Cut Or Conditioned For Polishing, Derusting, Surface Cleaning Detail Introduction :

Zinc cut wire shot - As Cut or Conditioned

Appearance is bright. The density of zinc shot is higher than aluminum, hardness softer than steel, then it can deburr products without wearing down the surface. Widely used for deburring and surface treatment of zinc and aluminum cast parts.

Chemical composition of zinc shot

Product | Grade | Chemical composition (%) | Density | Hardness | ||||

Zn | Fe | Al | Cu | Co | ||||

Zinc cut wire shot - G3 Conditioned | 0#Zn | 99.99% | 0.004% | 0.003% | 0.001% | 0.003% | 7.1g/cm³ |

45-60HV

|

Zinc cut wire shot - As Cut | 0#Zn | 99.99% | 0.004% | 0.003% | 0.001% | 0.003% | 35-55HV | |

Size Available:

0.6, 0.8, 1.0, 1.2, 1.5, 1.7, 2.0, 2.3, 2.5, 3.0 mm

Telephone :+86 157 6285 8378

Telephone :+86 157 6285 8378 WhatsApp :+86 157 6285 8378

WhatsApp :+86 157 6285 8378 Email :

Email :